While speaking about brazing vs welding vs soldering, it could be challenging to determine the right metal or material joining technique. Though each of these procedures is used to merge a couple of pieces of metal and other materials, they can be valuable to seal openings in metal parts.

Meanwhile, the decision to use these methods may depend on the types of materials you want to join. In addition to the type of materials, it may depend on applications and the needed strength.

Brazing VS Welding VS Soldering

These metal joining methods may work differently, but they have a few similar things. If you have to decide on one technique from these, you may need to have the following details about them:

What is Brazing

Brazing is one of the key procedures to join metals together. Indeed, brazing is similar to soldiering, which uses a filler metal, flux, and heat for joining metals. When you talk about brazing, a flux solution will be applied between the metal pieces you have to merge and the filler metal.

You must know that this type of metal-joining method is used to merge kitchen cutlery, jewelry, automotive engines, and other diverse uses. Brazing technique can be different from soldiering because it uses a little more temperature.

Hence, this procedure is commonly used for extremely thin metals. Fundamentally, brazing is beneficial because:

- Brazing is cost-effective for multi-part and multifaceted joining

- You can use it for joining non-metals and different metals

- Brazing does not need any secondary process as it gives a clear joint

- You do not give to melt the base metals

What is Welding

Welding is yet another metal-joining method often used for or joining materials and methods. Compared to other kinds of metal-joining methods, welding uses a high-heat for melting down the parts together.

Once after melting the parts together, it needs to cool them for fusion. Consequently, the welding becomes one of the top techniques which prevent melting the base metal but still gives the desired assemblies.

Technical procedures require welding a little more than other procedures. Since there are different kinds of welding techniques, they all are ideal in numerous conditions. Underwater welding is probably the most unforeseen application of the welding.

You can prefer the welding technique because:

- Welding is probably the only reliable process you can use for merging large sections of metals and materials

- Compared to other metal-joining methods, it is very affordable

- Welding is known for providing tight and strong seams and joints

- In many applications, residue removal is not necessary

What is Soldering?

If you have to join various kinds of metals, then soldiering becomes yet another commendable process. In this type of process, two or more metals are joining together by melting the solders. When you give preference to this technique, it allows filling gaps and joints with a filler metal.

We all know that the adjoining metals have a higher melting point, whereas the filler metals have a lower melting point. You do not need to melt pieces in this particular process. Soldering does not melt the workpieces as it only heats the solders.

Therefore, you might have seen more uses of soldiering in electrical parts. Since soldering does not need any high process temperature, it can become a worthwhile metal-joining procedure you should use.

Soldering is a good metal-joining technique because:

- Soldiering does not need a high process temperature

- It helps in merging thin-walled parts very efficiently as well as the dissimilar materials

- Also, soldering heats the solders, and it does not melt the base metal

By now, you have got some basic details about brazing, welding, and soldering. Accordingly, you might have a little more excitement to explore brazing vs welding vs soldering right now. Let us know how these metal-joining methods work:

How Does Welding Work

Since welding techniques are different as per their usage, it cannot be easy to understand its working procedure. You might have already here about the gas metal arc welding, shielded metal arc welding, and gas tungsten arc welding like other similar techniques.

So, you have to be clear about understanding each welding procedure or technique differently. Meanwhile, you may know the gas tungsten arc welding, gas metal arc welding, and the shielded metal arc welding, they all demonstrate the arc welding.

Before you understand the welding technique’s working process, you must know these methods have their unique pros and cons. shielded metal arc welding can be an affordable and convenient welding technique. Conversely, the gas tungsten arc welding is messy to learn.

Torch welding is another excellent method of welding which people use all over the globe today. When you use this process, make sure you are clear that it includes an oxyacetylene torch for melting the welding rod and workpieces.

Professional welders will control the welding rod as well as the torch carefully. In industrial operations, this type of welding method is not that much popular. For normal repair and maintenance works, torch welding is still a useable welding method.

No products found.

Let us know how arc welding works

Arc welding is one of the popular types of valuation techniques. Hence, it employs an electric arc for melting the materials and metals for merging some joints. Moreover, the arc welding uses the welding rod, also known as other filler material during the process.

A grounding wire will be attached to the machine as well as the metals you want to well. An electric arc will be generated if you successfully connect the ground wire and the metals. Now, the arc will melt the pieces along with the welding rod.

As a result, the process of arc welding will be completed. You must know that welders have to keep their eyes on the detail for joining the pieces.

Whenever the welding rod melts, the welders will continuously fill the filler material into the gaps and openings. In addition to the procedure, welders have to avoid holding the arc very closely as it can create mess welds.

How Does Brazing Work

When we use brazing for joining metals and materials, we can expect to have leak-proof and strong connections. Since brazing permits the flow of melted filler metal between the openings and gaps, it produces authentic and trustworthy results.

Fundamentally, you need to reserve a clearance between the base metals to permit the capillary action which brazing uses. As per the experts, close clearance is required between the base metals. More importantly, the joint strength can get decreased if you increase the clearances.

You may need to look at the size and nature of the metals you want to join to determine in the allowance. If you merge joints with brazing, they will be unique and different from the welded joints. Unlike other methods, brazing will not melt the base metal.

No products found.

By now, you need to know that the brazing technique works by making a metallurgical bond between the surfaces of metals you want to join and the filler metal or the metal rod. Capillary action is probably the principal by which the metal rod is melted through the joints for creating the bonds.

Whenever you talk about brazing operations, experts have to apply the heat extensively to the base metal. Moreover, the metal rod is brought back into the play for contacting the heated parts. The brazing method uses capillary action for drawing and the filler metal for heating the base metal.

Now, you might have understood the working scenario of the brazing technique.

How Does Soldering Work

If you have to merge dissimilar metals and materials, soldering will be a great procedure to use. Soldering technique mainly uses a melting solder for joining various kinds of metals you want to join together.

In this process, you have to use a hot iron for melting the metal alloy or solder, which comprises lead and tin. Fundamentally, the hot iron will be heated above 600 degrees Fahrenheit temperature. Once the metal alloy is heated, it is possible to create strong electrical bonds.

As depicted earlier, the soldering procedure will use a solder melted by a heated iron. You may need to connect a temperature controller to heat iron for undergoing this procedure. Solders are heated above their melting points and temperatures.

No products found.

As a result, they can get melted, and then cooling will create soldered joints. You have now successfully understood how brazing, welding, and soldiering metal-joining techniques and methods work.

With the help of the mentioned above paragraphs, it might be clear which metal-joining method is efficient in the working process. Hence, you can easily move forward to differentiate these particular techniques of joining metals and materials:

Brazing VS Welding VS Soldering: Different Types

Different Types of Welding

So far, you have successfully become familiar with the introduction and working procedures of various metal-joining methods. Accordingly, it is imperative to be familiar with the different types of welding methods.

Arc welding is one of the most used types of welding techniques today. Fundamentally, the types of welding techniques are differentiated according to their applications and uses. Here are the main types of welding techniques you need to know right now:

Gas Welding

Since gas welding is not in that much use, it is still a popular type of welding technique. Gas welding is a procedure in which metals are melted and joined with a heating element. You may use a reaction of Oxygen and fuel gas for heating the metals.

The TIG welding technique has overridden the gas welding method. Car exhausts may need this type of welding a little more than others.

Gas Metal Arc Welding- MIG/GMAW

MIG is another full use form of welding, which is extremely friendly for new welders. MIG welding is also known as gas metal arc welding. Compared to other welding techniques, it is a very swift process.

However, this type of welding is not that useful for outdoor use. You can merge dissimilar metals that have different thicknesses by using this particular welding technique. You can expect to produce premium welds through this method.

Gas Tungsten Arc Welding -TIG/GTAW

Gas tungsten arc welding is another important type of welding techniques you need to know. If you want to use this welding technique, you may know it is very versatile.

New people may take a little more time to understand this complex welding technique. In this method, non-consumable tungsten will be used along with the filler metal. The TIG welding method is mainly known for producing clean and premium welds.

Shielded-metal Arc Welding- Stick/SMAW

Shielded metal arc welding is very difficult to understand than other kinds of welding techniques. Compared to other techniques, this type of method is not a clean one because cleanup is required.

You can use a stick welding method even in rainy and windy conditions. You do not have to use any external shielding gas in this method, which can lead you to save more money.

FCAW- flux-corded Arc Welding

Identical to MIG welding, this type of welding technique is known for producing consistent and premium welds. In addition to the application, this method is very fast.

Once you have the right filler metal, you can use it in all positions. For outdoor welding works, this type of welding method is extremely acknowledged.

Plasma Arc Welding

When it comes to aerospace applications, plasma arc welding will be the most considerable welding technique. Though it is similar to TIG welding, it is different as it provides premium quality.

If you use this method, you can expect to have smoother and cleaner welds. Plasma arc welding almost guarantees to deliver aesthetically pleasing and highly strong joints.

Electron-beam Welding

Electron-beam welding is another considerable type of welding where the welders use a high-velocity beam. For welding two or more materials together, this method will use the heat produces through the kinetic energy.

Compared to other methods, this type of welding is mainly used by machines. So, it can be one of the rear welding techniques, you know. Hopefully, you have successfully become familiar with different types of welding methods now.

So, it might be easy to differentiate brazing vs welding vs soldering without further doubts.

Different Types of Brazing

Brazing methods are usually categorized as per the heating methods used. With this type of metal-joining method, it is possible to get clear welds. The brazing method certainly diminishes the requirement for any secondary finishing.

Essentially, you have to know that the brazing technique is carried out in two particular ways. Either you have to use the diffuse heating technique or the localized heating technique.

Both localized heating techniques and diffuse heating techniques have a few other common types. Let us try to become familiar with the different types of brazing techniques:

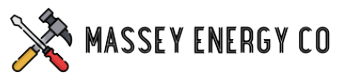

Induction Brazing

By now, you need to introduce yourself to the induction brazing. In this type of brazing method, the heat will be created by using swiftly changing current. As well, the hate will be inducted into the workpiece is with the help of an adjacent coil.

You may need to use a high-frequency induction heating element for this type of brazing technique. Compared to other brazing techniques, this particular technique gives quick and clean results.

You can easily control this particular method to have the best results.

Torch Brazing

Torch brazing is yet another popular localized heating technique in all brazing techniques. In this type of method, a fuel gas flame will be used to curve the filler metal and generate the heat required for melting.

You are allowed to use hydrogen, acetylene, and other particular gasses with air to generate a flame. You might get strong, corrosion-resistance, and highly durable joints through this particular brazing method.

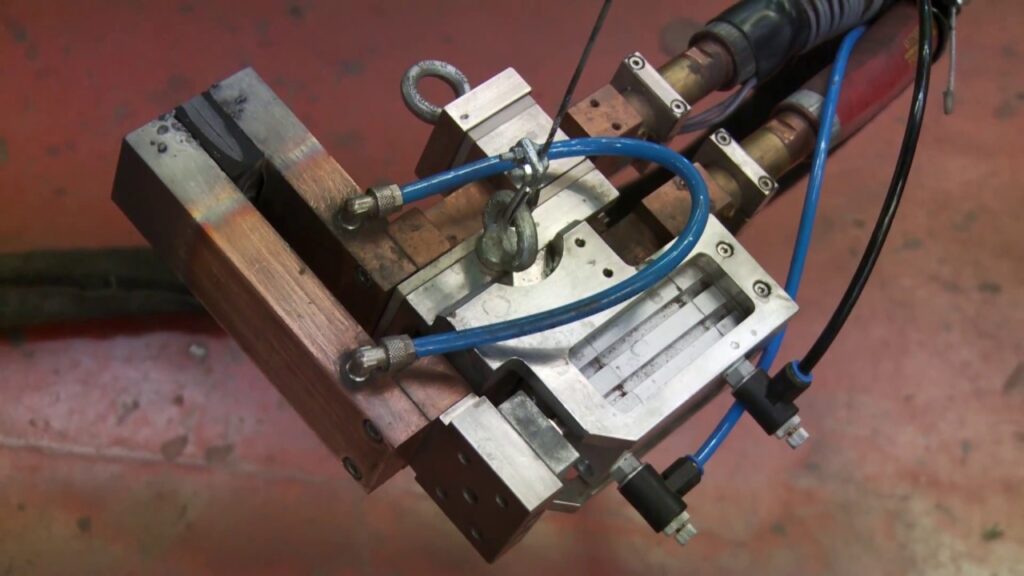

Resistance Brazing

Resistance brazing is another productive procedure in which an electric current will be used for producing the heat. When you talk about the resistance brazing, the resistance will be formed through the heat generated.

Fundamentally, it is a very safe and authentic brazing technique you can use.

Dip Brazing

You have to join pieces of metals in the dip brazing process by flowing the metal filler between the gaps and openings at low temperatures.

Furnace Brazing

Furnace brazing technique is commonly applicable in plenty of brazing operations and industrial applications. Of course, you can go to this particular method because it is extremely flexible.

Both experienced and unskilled laborers can carry out this work for mass production.

Different Types of Soldering

As we already know, soldering is a much acknowledged metal-joining technique for merging pieces of metals. Though soldering is an easy automatic procedure, it often needs low power and low process temperature.

In this type of method, we have to use a solder, which will work as a separate alloy. Sufficient ventilation is always required when you have to undergo the soldering procedure. If you have very sensitive components, make sure to use those components in the end.

Moreover, you need to check the joints before you start the process. You have to use this shoulder between the parts you want to bond. Once you heat the shoulder, you have to wait until the solder gets cool.

If you see the solder has become hardened and cooler, you can ensure you have completed this process quite efficiently. Here are the main types of soldering techniques you should know right now:

Hard Soldering

Hard soldering is one of the methods you can prefer while joining pieces of metals through the soldering technique. Compared to the soft soldering, hard soldering includes the use of higher temperatures for melting the solders.

You can go for either silver or brass as per your interest. In addition to the solder material, you need a blowtorch for melting. According to the experts, this type of soldering method can create highly stronger joints.

If you use silver as a preferable solder material, you have to undergo the hard soldering. Though you can melt silver at a lower temperature, it still looks very costly. Accordingly, you have to prefer this option if you have to merge pieces of silver, brass, and copper.

Soft-soldering

If you have seen many plumbing and electronics works, you might have seen using the soft-soldering method a little more. The soft soldering method is capable of creating clear electrical bonds and connections.

So, this type of soldering technique is used for joining connectors and copper pipes. You can go for any solder made from the metals or tin for performing this method. When you want to ensure a perfect fit, this will be a leading method to use.

You can use a gas-powered soldering iron and an electric iron for soldering. Compared to other types of soldering methods, this method can create weaker bonds.

Braze Soldering

However, the braze soldering is another important brazing technique used for merging the terminals of base metals with a metallic space filler. This particular soldering technique is known for producing strong joints.

Atomic magnetism and diffusion will be united by this method. Hence, it could be an extremely reliable method. You can use a space-filler like a brass metal, which can give the desired results.

Silver Soldering

Silver soldering is supposed to be an unknown method for connecting small parts. In this particular method, you have to use a space-filler metal, an alloy with silver. Since silver can give a flexible individuality, it is not one of the most used soldering methods.

Conclusion

So far, you have successfully distinguished brazing, welding, and soldering metal-joining techniques with full details. Perhaps, it is clear now which of the mentioned above metal-joining method is preferable as per their working procedures and classifications.

Brazing can assist in authentically merging metals, whereas welding is still the most used method for joining metal pieces. In addition to brazing and welding, soldering metal-joining method has its unique perks and pitfalls.

Now, professionals can easily get a clear idea about using the best metal-joining method among these mentioned techniques. Although these three mentioned methods are different, you have to choose the one as per your work type.

Thus, this is all about the introduction, working, and types of various metal-joining techniques.